Product Series :MCA / TYPE (Amorphous and Nanocrystalline Cores)

Feature

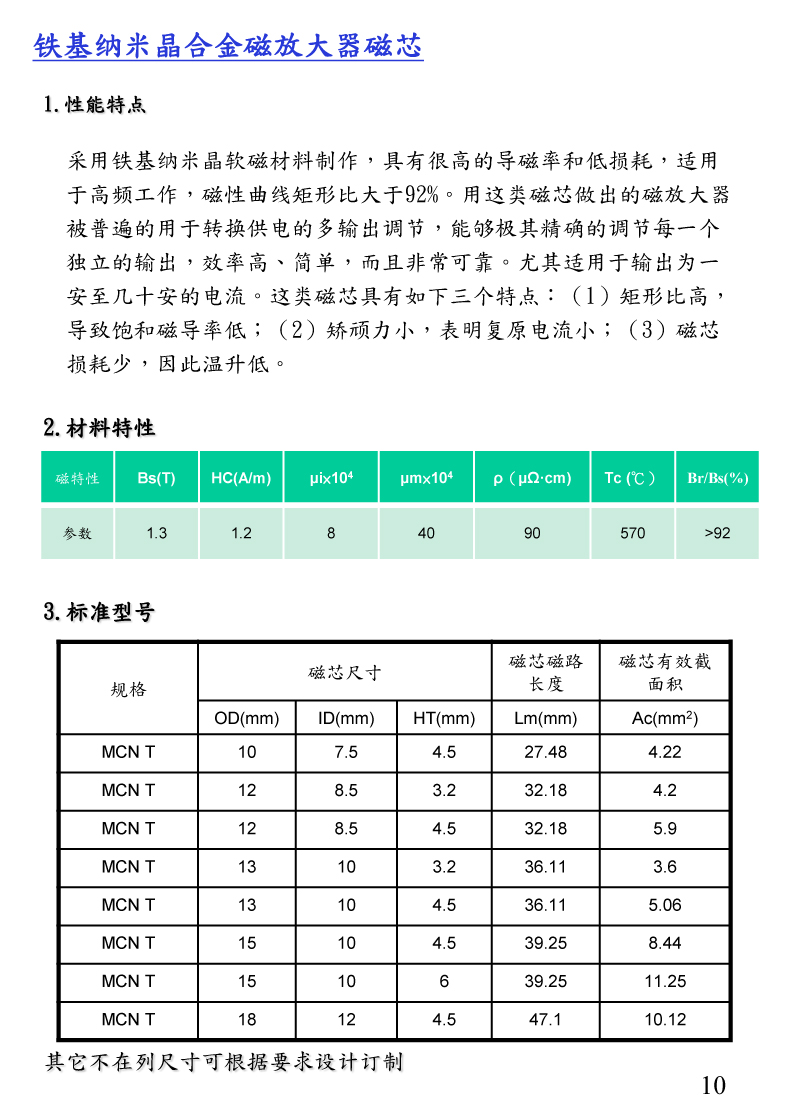

Nanocrystalline materials have high saturation magnetic induction strength and initial permeability, which is beneficial for improving the detection sensitivity of leakage protectors. Moreover, the coercive force of nanocrystalline materials is small and the rectangular ratio is high. When working at higher frequencies, only a small excitation current is required to reach the saturation state of the magnetic core, which helps to reduce power consumption and simplify circuit design.

Technology is developing towards high-frequency, high-efficiency, high stability, high-power, small-scale, and energy-saving directions.

Amorphous alloys utilize the rapid cooling and quenching technology of liquid metals to obtain amorphous microstructures that do not possess traditional alloys. On the basis of amorphization, metal thin strips undergo appropriate heat treatment, which are called nanocrystalline alloy strips.

Nanocrystalline (also known as ultramicrocrystalline) materials have high saturation magnetic induction, high permeability, low coercivity, low high-frequency loss, good hardness, wear resistance, corrosion resistance, good temperature and environmental stability. Their excellent comprehensive properties replace the application of permalloy, silicon steel sheet and ferrite in power electronics technology, showing the characteristics of small size, high efficiency, energy saving, etc, It has the best cost-effectiveness among all current metal soft magnetic materials.

Application

● Common mode choke inductor

● Output filter inductor

● Power harmonic inductor

● PFC (Power Factor Correction) inductor

● Medium and high frequency transformer

● Precision transformer

● Anti DC component transformer

● Saturation reactor

● Wireless charging technology etc.