Development and Applications of Mingci Electronics Amorphous Nanocrystalline Series Inductors

Development and Application of Crystal Nanocrystalline Magnetic Rings, Common Mode Inductors, and Saturable Inductors

Overview

With the rapid development of the electronic information industry, the three main markets of high-frequency switching power supplies: communication, computers, and consumer electronics will also develop rapidly. Whether it is an AC/DC or DC/DC power supply, in addition to power transistors, main transformers, chokes, and other inductors made of high-performance magnetic materials (such as anti noise filters) are extremely important components, and their magnetic performance and size directly affect the conversion power and power density of the power supply.

The band thickness and resistivity of amorphous nanocrystalline soft magnetic alloy materials determine that their optimal application frequency range is in the KHz frequency band, which coincides with the current high-frequency switching power supply frequency band. Therefore, the research, development and application of amorphous nanocrystalline alloy magnetic devices for high-frequency switching power supplies are very active. Over the years, we have not only researched and developed various specifications of amorphous nanocrystalline alloys, such as O-type, C-type, and CD-type switch power transformer cores, for use in intermediate frequency power supplies, inverter power supplies, program-controlled switches, and power transformers for inverter welding machines, but also adjusted their soft magnetic properties through heat treatment methods, processes, and processing techniques, We have developed a series of inductance cores with effective permeability μ e ranging from tens to tens of thousands to meet the needs of inductance characteristics, another important type of magnetic device in high-frequency switching power supplies, especially various inductance devices for high-frequency high-power and high current switching power supplies. The successful application of these high-tech products not only improves the technical level and production capacity of amorphous nanocrystalline alloy materials and devices, but also promotes the development of amorphous industrialization.

With the wide application of high-frequency technology, people pay more and more attention to electromagnetic compatibility (EMC), noise pollution and other issues. Anti EMI technology has become a new technology and new industry. It is more urgent to solve the electromagnetic compatibility of electronic equipment. Various magnetic devices such as anti electromagnetic interference and noise suppression have been widely used. One of the key components of these devices is inductance devices.

We have utilized the performance characteristics of amorphous nanocrystalline alloy materials and combined them with previous work to develop and apply a series of inductance devices using amorphous nanocrystalline alloy materials. We have not only carried out relatively mature transverse field annealing methods and amorphous nanocrystalline inductance iron cores with air gaps, but also pioneered the research and development of iron based nanocrystalline alloy magnetic powder cores and iron based amorphous gapless wide constant conductivity inductance series product devices in China, We have achieved good application results and have now formed a series of inductance iron core products with effective magnetic permeability ranging from tens to tens of thousands, meeting the needs of different users.

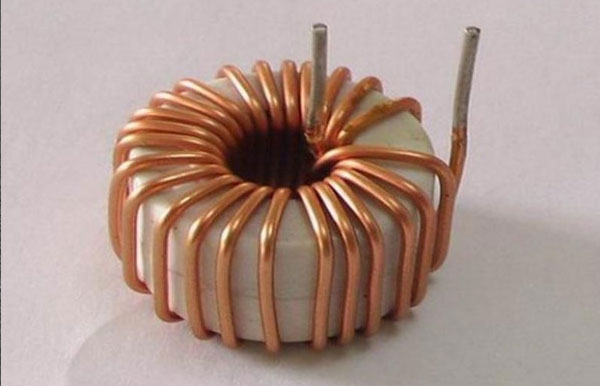

Common-mode inductors, saturable inductors, and peak suppressors are all in small signal operating states, requiring the larger the inductance, the better. Based on L=0.4 π μ eN2Se/100 × In the formula l (μ H), μ e is the effective magnetic permeability S is the effective cross-sectional area (cm2) N is the number of winding turns

l: The average magnetic circuit length (cm) indicates that for magnetic cores of the same size and specification, the higher the effective permeability μ e, the greater the inductance. Therefore, common mode inductors, saturable inductors, and peak suppressors prepared from amorphous nanocrystalline alloys have the following performance characteristics:

1. High effective magnetic permeability, large inductance, and small volume;

2. Low playability and low wear and tear;

3. The number of winding turns is small, and the distributed capacitance is small;

4. High saturation magnetic induction, effective in handling noise spikes;

5. High Curie point and good temperature stability;

6. Good frequency characteristics; The high magnetic permeability of amorphous nanocrystalline alloys can greatly reduce the core size of common mode inductors and peak suppressors, especially in high current and high-power applications. Choosing this type of alloy as a common mode inductor core has good cost-effectiveness. Even compared to cheap high-performance ferrite, it is not inferior. Generally, the magnetic permeability of this type of ferrite is around 10000, while the magnetic permeability of iron based nanocrystalline alloys can generally reach 80000-120000. Under the same inductance requirements, the magnetic core size of the latter is only 1/8-10/10 of the former, and the price difference between the two is about 6 times. Obviously, iron based nanocrystalline alloys have a certain competitiveness. In a military three-phase switching power supply, with a working current of 100A, one φ one hundred and thirty ×φ ninety × 30mm conventional microcrystalline alloy magnetic core replaced 4 φ one hundred and thirty ×φ seventy × 50mm high-performance ferrite core with some performance surplus. Due to the widespread application of switching power supply technology, common mode inductors that resist electromagnetic interference have become essential components in many electronic devices. In addition to considering the 50Hz power frequency, there are also certain requirements for high-frequency performance. The use of amorphous nanocrystalline materials with high magnetic permeability and low Br to make such inductive devices will be the best choice.

Table 1. Magnetic properties of iron-based nanocrystalline alloy common mode inductors

A major drawback of switching power supplies is that they are prone to noise interference. The noise is mainly caused by the rapidly changing high-voltage switching current and pulse short-circuit current in switching power transistors and switching rectifier tubes. Currently, most methods use non-linear saturated inductors to suppress reverse recovery current spikes to suppress noise. The inductance device in this type of peak suppressor has a small volume and large inductance, which requires the inductance magnetic core material to have high magnetic permeability. In the past, cobalt based amorphous materials have been used to make this type of saturable inductance device. Due to the high Co content and high price, in recent years, by adjusting the composition of Fe based nanocrystalline alloys, improving processing and heat treatment processes, etc, Developing 4Fe based nanocrystalline alloys to replace Co based amorphous alloys to produce small-sized saturable inductance series iron cores, greatly reducing the cost of iron cores and meeting the market demand for noise interference resistant devices; Nowadays, this type of iron core is also promoted and applied as magnetic amplifier iron core with higher rectangular ratio requirements.

Transverse field heat treatment annealing method

The preparation of linear amorphous nanocrystalline alloy inductance core by transverse field heat treatment annealing is made by using the previous permalloy magnetic field treatment method. The magnetic permeability of the core μ e is mainly determined by the size of the external magnetic field. Due to the cumbersome processing of this type of inductor core and the relatively small linear range, except for inductance devices with high linearity requirements, most of the iron cores processed by this method are not used as inductors, and the market demand is not too large, so there is not much description.

Non gap wide constant conductivity inductance materials and devices: Iron based amorphous non gap wide constant conductivity inductance devices are a new application field of Fe based amorphous alloy materials. Although there were research reports in this field both domestically and internationally in the 1980s, it did not achieve industrialization, application, and commercialization. Since the 1990s, the United States, Japan, South Korea, and other countries have successively used the United States' Fe based amorphous alloy to develop amorphous alloy inductance iron core series for high-frequency inductance devices such as AMC, AMB, etc AMS and other inductors have the following performance characteristics: low high-frequency loss; High magnetic permeability; High saturation magnetic induction Bs; Small size; It has linear permeability within a certain magnetic field range and is widely used in switching power supplies (SMPS), DC/DC, AC/DC converters, UPS, noise suppressors, etc. We have developed and applied this type of gap free wide constant conductivity inductance material based on Fe based amorphous alloy 2605S-2. Through material and processing technology research, we have developed an effective magnetic permeability range of μ e from 200 to 20000, with an outer diameter of the iron core specification φ 16~50mm, inner diameter φ The 8-30mm and 8-30mm series of gapless wide constant conductivity inductance devices meet the requirements of different users.